☏ +91-9810944301 ✉ pritpalcameotra@gmail.com

CREASING RULES

CREASING RULES

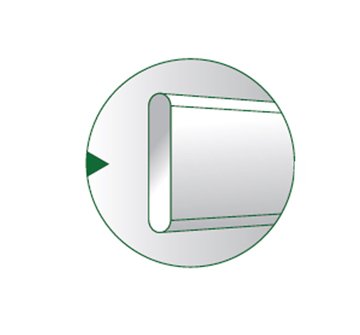

Creasing rules are an essential component in various industries, including printing, packaging, and paperboard conversion. A creasing rule is a tool used to create a fold or crease in a material, typically paper or cardboard, to facilitate folding or bendingwithout cracking or breaking. The rule is designed to compress the material, creating a localized area of weakness that allows for a clean fold.

Creasing rules come in various thicknesses, widths, and heights, depending on the specific application and material being used. For example, a 2-point creasing rule is suitable for thinner materials, while a 6-point or 8-point rule is better suited for thicker materials.

The height of the creasing rule is also critical, as it determines the depth of the crease. A taller rule will create a deeper crease, while a shorter rule will create a shallower crease.

In addition to the physical characteristics of the creasing rule, the material being creased also plays a significant role. The grammage, or weight, of the material affects the creasing process, with heavier materials requiring more force and a more aggressive creasing rule.

Creasing rules are commonly used in various applications, including packaging, printing, and paperboard conversion. They are an essential tool for creating folds, scores, and creases in materials, enabling the production of a wide range of products, from simple paper folders to complex packaging designs.

There are different types of creasing rules, including national scoring rules, hinge crease rules, and twin rule crease rules. Each type of rule is designed for specific applications and materials, and selecting the right rule is critical for achieving a high-quality crease or fold.